Development of a Cyclo-Rotor UAV Scale Application

In recent years, Unmanned Aerial Vehicles (UAVs) have undergone rapid advancements, reshaping sectors such as agriculture, logistics, entertainment, and defence. Improvements in efficiency, manoeuvrability, endurance, and flight precision have encouraged researchers to investigate innovative rotor technologies. Among these emerging concepts, the cyclo-rotor has reappeared as a promising candidate capable of redefining UAV performance.

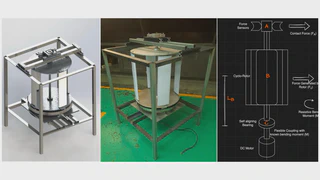

First introduced in 1909 in the USSR as the “Wheel Orthopter,” the cyclo-rotor was initially abandoned due to its structural complexity and excessive weight. However, modern advances in lightweight composite materials, computer-aided engineering, and precision manufacturing have revived interest in this design, enabling higher aerodynamic efficiency and reduced rotor mass.

Unlike conventional rotary wings that use twisted blades, the cyclo-rotor employs multiple airfoils mounted around a rotating cylindrical frame. This unique configuration offers several advantages, particularly for UAV-scale applications. Its ability to generate vertical take-off and landing (VTOL) capability makes it highly effective in confined environments where fixed-wing aircraft cannot operate—such as dense urban settings, disaster zones, and covert military missions.

Cyclo-rotors also allow full 360-degree thrust vectoring on each rotor, providing superior manoeuvrability compared to traditional UAV rotors. This feature enhances stability in heavy gusts and enables precise control in tight operational spaces. Although research into cyclo-rotor technology is still in its early stages, its potential to expand UAV capabilities is significant. Challenges related to efficiency and durability remain, but the considerable performance benefits justify continued exploration and development.