Design and Development of a Glider Wing Tailored for Surveillance Applications

Surveillance in coastal regions has traditionally relied on costly manned systems, creating a growing demand for affordable alternatives with optimised aerodynamic and structural performance. This project addresses that need by developing an integrated design framework for a surveillance glider that unifies aerodynamic design, structural analysis, and composite material characterisation.

A systematic methodology was established by combining classical aerodynamic theory with modern computational tools. Lifting-line theory formed the foundation for the analytical aerodynamic model, which was further refined using XFLR5 to improve predictions of aerodynamic behaviour and verify both longitudinal and lateral stability. Computational Fluid Dynamics (CFD) simulations were used to analyse pressure and velocity fields, as well as overall flow behaviour around the glider.

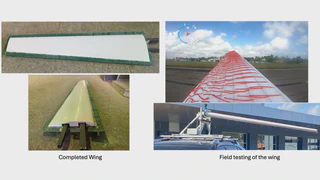

For structural development, a dedicated analytical tool was created to automate the sequential calculations required during the design process. Using the aerodynamic loads and input parameters, it computed force distributions, bending stresses, rib and stringer requirements, and performed necessary safety checks. Classical Lamination Theory (CLT) was applied to predict composite behaviour, supported by tensile testing for material validation. Wing plugs were CNC-machined, with separate plugs and moulds produced for efficient assembly. Wing skins were fabricated using Vacuum-Assisted Resin Transfer Moulding (VaRTM), while spars were produced via hand layup. Divinycell H80 PVC foam was used to manufacture ribs and stringers.

Structural validation was carried out through sandbag testing to measure deflection, and on-ground flight tests were conducted under real atmospheric conditions to assess lift characteristics and flow behaviour. This end-to-end process, from theory to fabrication and testing, ensures strong alignment between analytical predictions and real-world performance.

Future work includes expanding test conditions, refining CFD and FEM models to better capture real-world effects, and improving analytical accuracy. A designer-oriented, user-friendly platform integrating aerodynamic and structural modules is also under development.