Design and development of a small passenger vehicle chassis with improved crash-worthiness and aerodynamic performance for small-scale manufacturing

As the final-year capstone project of our Bachelor of Science in Mechanical Engineering degree, I with two colleagues, Mr. Nipuna Jayanath and Ms. Diananjalee Harindra undertook the design and development of a small passenger vehicle chassis with enhanced aerodynamic performance and crashworthiness. This project was conducted in collaboration with a small-scale automotive design and manufacturing company in Sri Lanka, coordinated through our project supervisor, Mr. Sasiranga De Silva.

The work formed part of a broader multi-project initiative aimed at establishing indigenous automotive design and manufacturing capabilities in Sri Lanka, an achievement not previously realised in the country. Although several vehicle models have been assembled locally, their designs and key components, including chassis structures, have historically been produced abroad.

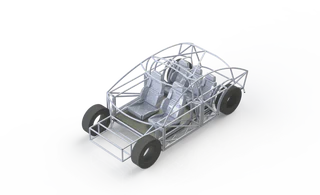

Building on the knowledge and experience gained from our involvement in the Formula Student project, our team sought to develop an experimental chassis concept suitable for a compact electric passenger vehicle. A key objective was to create a structured framework for designing a spaceframe (tube) chassis with improved aerodynamic and crashworthiness characteristics. This framework could then serve as a reference for small-scale manufacturers in Sri Lanka as they develop future vehicle designs with diverse performance requirements.

The aerodynamic performance of the vehicle was assessed through a series of Computational Fluid Dynamics (CFD) simulations aimed at optimizing several key design features, including the front fender geometry, front windscreen angle, side-mirror configuration, and roof profile. For each design element, a separate set of parametric optimization simulations was conducted. The selected optimal features were then integrated to form the initial detailed vehicle design. Subsequent CFD studies were performed to refine the overall aerodynamic coherence of the vehicle, ensuring that all components functioned synergistically to enhance aerodynamic efficiency. The primary objective of the optimization process was to reduce aerodynamic drag, while ensuring that certain components, such as the front fender, provided adequate airflow for heat-transfer requirements.

Based on the optimized exterior geometry and the provided suspension layouts, an initial chassis design was developed with emphasis on structural strength, rigidity, manufacturability, lightweight construction, and cost-effectiveness. The crashworthiness of the chassis was evaluated using Explicit Dynamics Finite Element Analysis (FEA) simulations, conducted with the LS-DYNA solver within the SIMULIA Abaqus software suite. Standard crash test scenarios defined by the Euro NCAP safety rating system, one of the world’s leading frameworks for assessing vehicle safety, were recreated in the simulation environment. Through multiple simulation iterations, the frontal and side impact structures were refined to meet Euro NCAP performance recommendations.

Following aerodynamic and crashworthiness optimization, the finalized chassis was fabricated at full scale. The manufacturing process began with cutting and bending steel tube sections to the required geometries, which were then welded into sub-assemblies. Using wooden jigs for alignment, these sub-assemblies were gradually joined to form the complete chassis structure. The full-scale prototype was a critical component in the broader multi-project initiative aimed at developing a small electric passenger vehicle. The design process, simulation results, and completed chassis were showcased at the “MechX 2019” exhibition at the University of Moratuwa.

As future works, experimental evaluation of the chassis torsional rigidity was planned to be evaluated using an industrial grade chassis straightening rig. Furthermore, as part of the electric car development project, this chassis was used in the first iteration of the experimental electric passenger vehicle.